UNITER HEAT GENERATORS

NEW GENERATION UPHOLSTERY MATERIALS

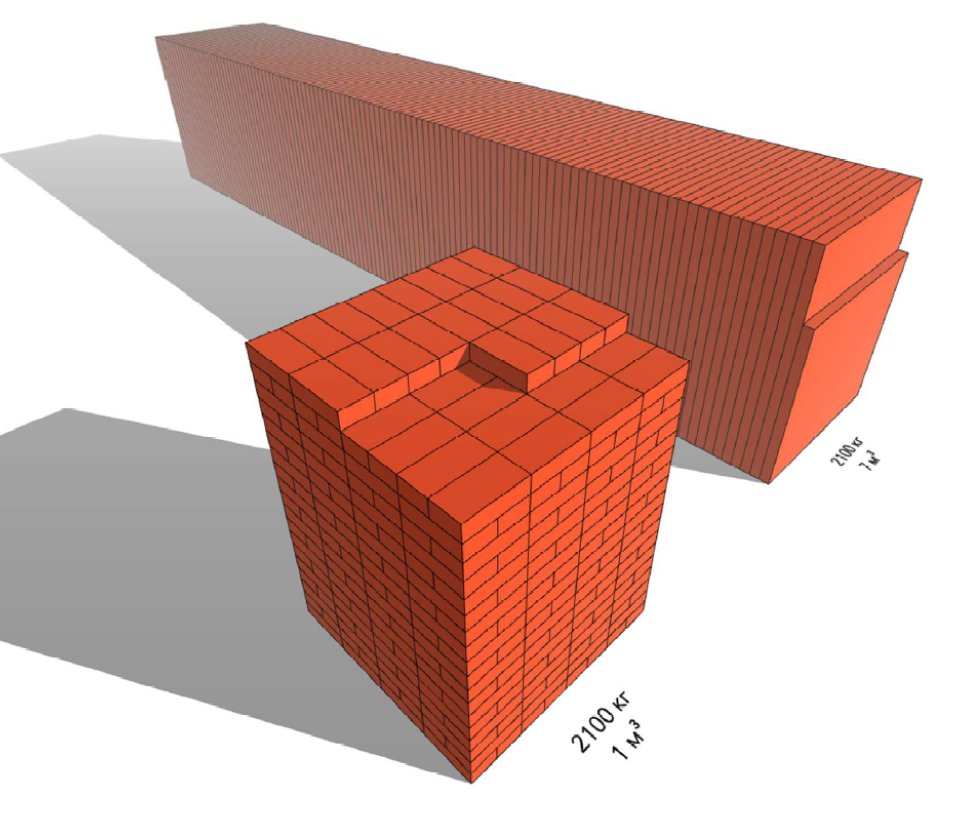

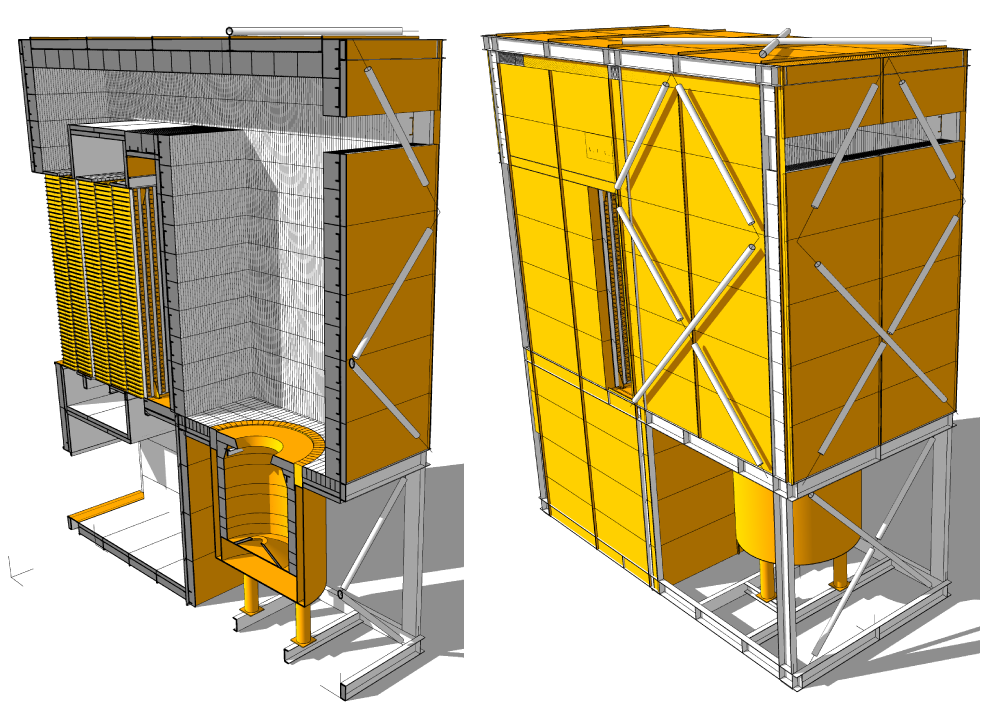

CERAMIC FIBER IS 7 TIMES LIGHTER THAN FIRE BRICK - REDUCED WEIGHT, SIMPLIFIED LOGISTICS

The use of modern solutions for lining high-temperature chambers allows you to significantly reduce the mass of the installation, which saves costs for the installation of foundations, transportation and installation of equipment.

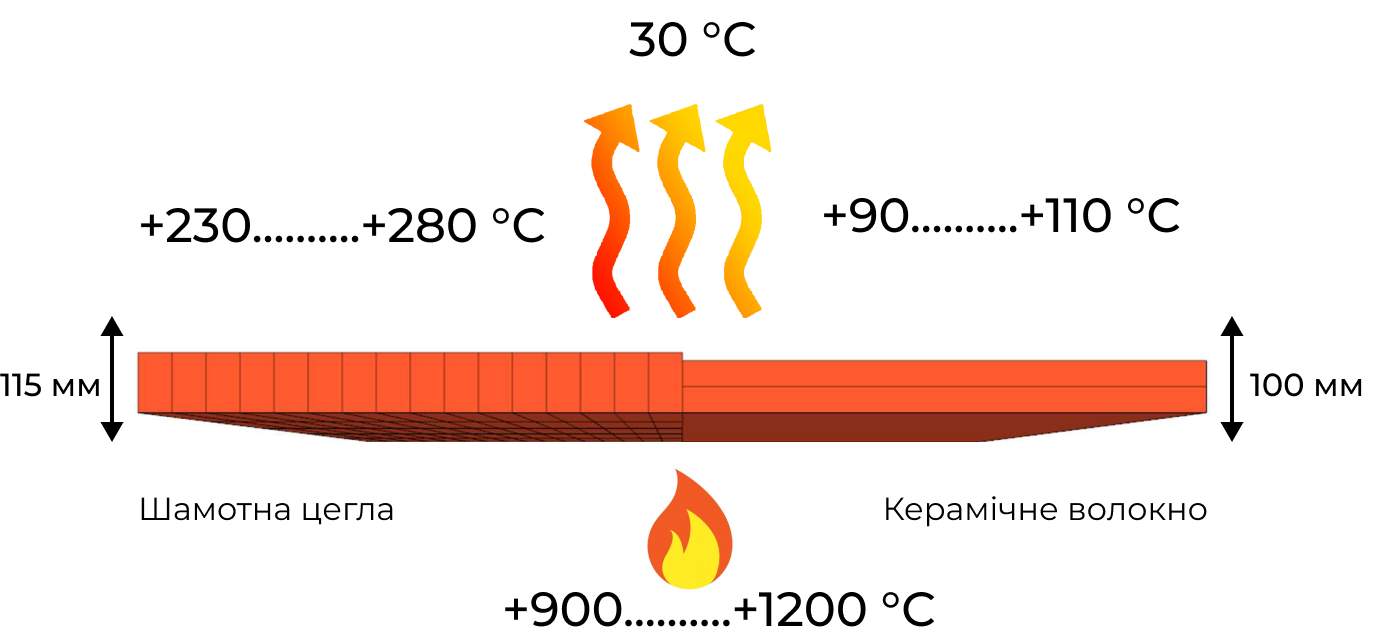

REDUCED HEAT CONDUCTIVITY

Ceramic fiber products combine the high fire resistance of classic fireclay, mullite materials and low thermal conductivity, resistance to thermal shocks of basalt, asbestos insulating materials

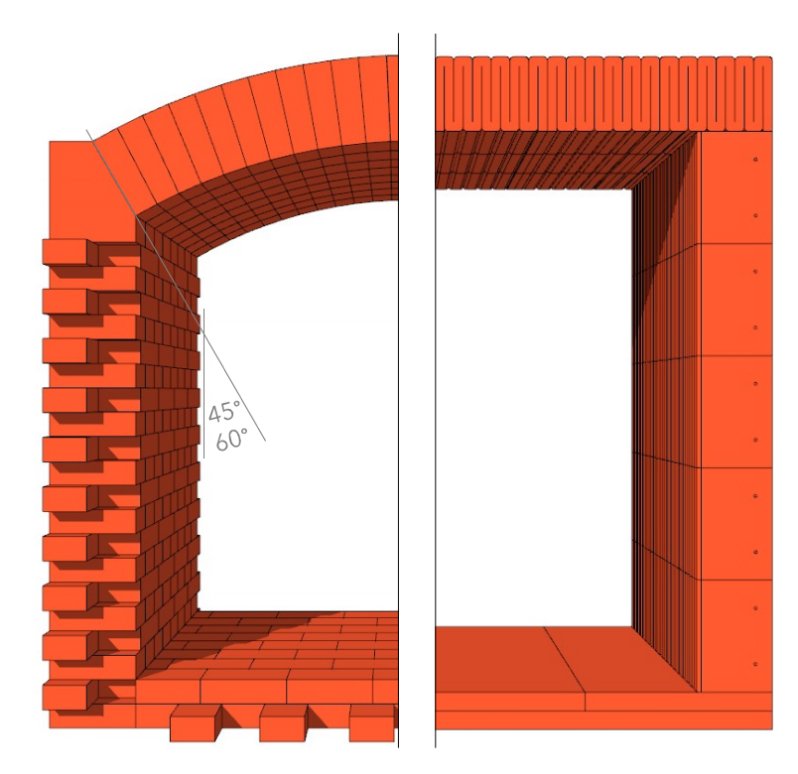

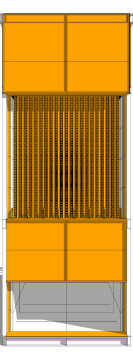

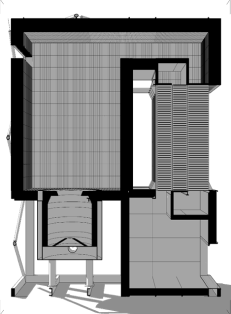

SIMPLIFIED DESIGN - EASY ASSEMBLY, CONTROLLED MANUFACTURING

The low density of the material makes it easier and more reliable to make the ceiling of the chamber flat, which increases the effective volume of the chamber with the same external dimensions compared to the classic arch vault of the chambers, and therefore the design is more compact

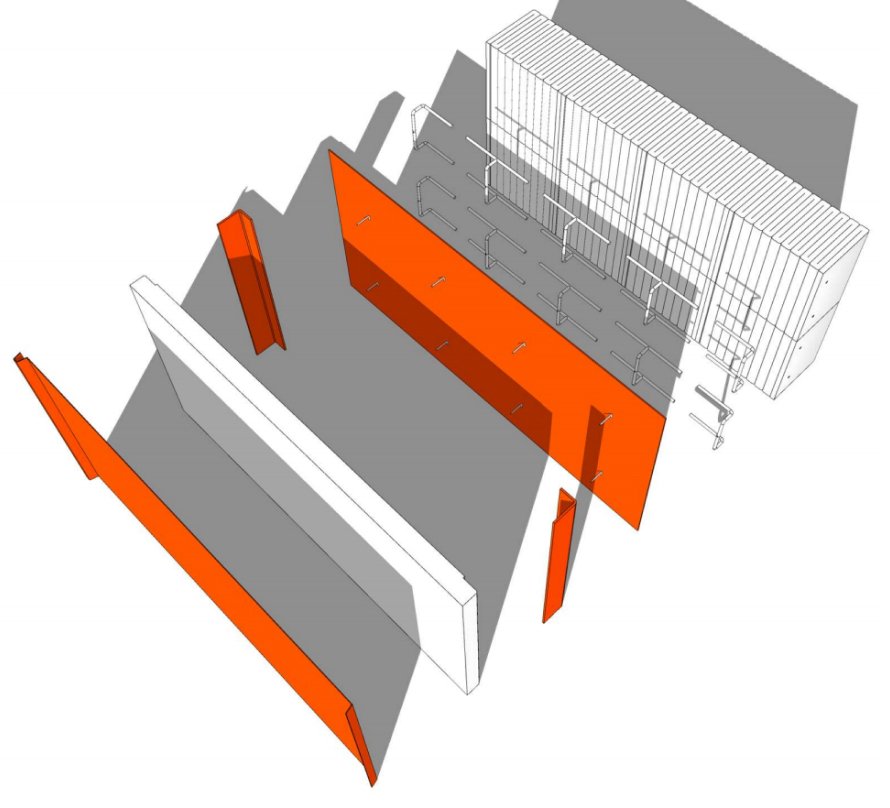

The structure of the new materials technologically allows the installation to be transported to the site of operation in large blocks, which means that most of the installation's components will be assembled in factory conditions under close supervision of the manufacturer, and the installation work will be shortened on the construction site

UNITER HEAT GENERATORS

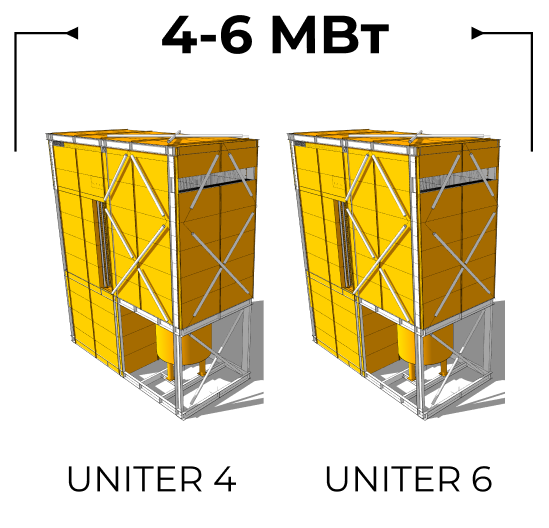

RANGE OF POWERS

UNITER 6

| MW | 4 | 6 | 8 | 10 | 12 | 15 | 18 | 24 | 30 | ||||||||||||||||||||

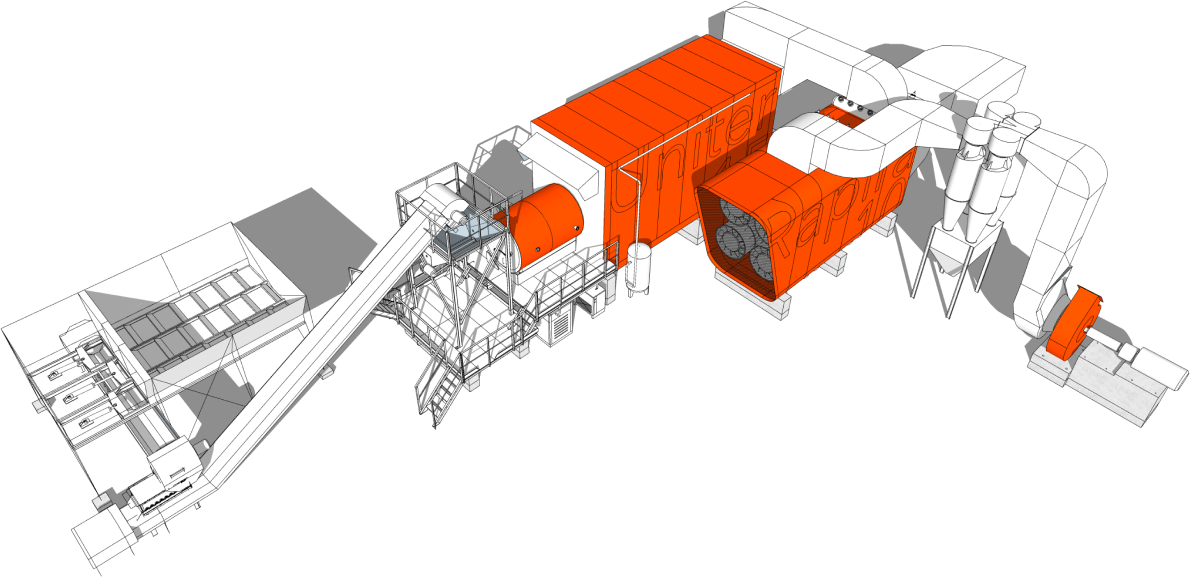

GRAIN DRYING COMPLEX EQUIPMENT

UNITER 4 / UNITER 6

UNITER 4 |

||||||||||||||||||||||||||||||

| 4 MW | ||||||||||||||||||||||||||||||

UNITER 6 |

||||||||||||||||||||||||||||||

| 6 MW | ||||||||||||||||||||||||||||||

Gas heat generator (direct heating)

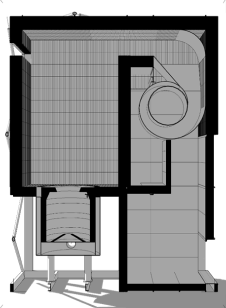

Enclosure of the performance chamber made of large-block elements

The module in the folded state is large enough to be transported by motor vehicle.

LOW AERODYNAMIC RESISTANCE

The low aerodynamic resistance of the heat exchanger on heat generators of small capacities allows not to use cold air supply fans.

2 VERSIONS

Depending on the customer's requirements, TEFF heat generators are available in 2 versions:

| GAS HEAT GENERATOR (direct heating) | UNITER 4 | UNITER 6 |

|---|---|---|

| Heat capasity of the burner, MW | 4,0 | 6,0 |

| Burner model | Samum 12/4 | Samum 12/6 |

| Efficiency coefficient of the heat generator, % | 95% | 95% |

| Thermal capacity of the heat generator, MW | 3,8 | 5,7 |

| Thermal stress, qv, kW/m3 | 220 | 330 |

| Fuel consumption (for sunflower husks), kg/h | 930 | 1 390 |

| Temperature of combustion products,°C | 800 | 800 |

| Volume of combustion products, m3/h | 32 100 | 48 000 |

| Camera width in the light, m | 2,4 | 2,4 |

| Camera height in the light, m | 4,8 | 4,8 |

| Camera length in the light, m | 3,0 | 3,0 |

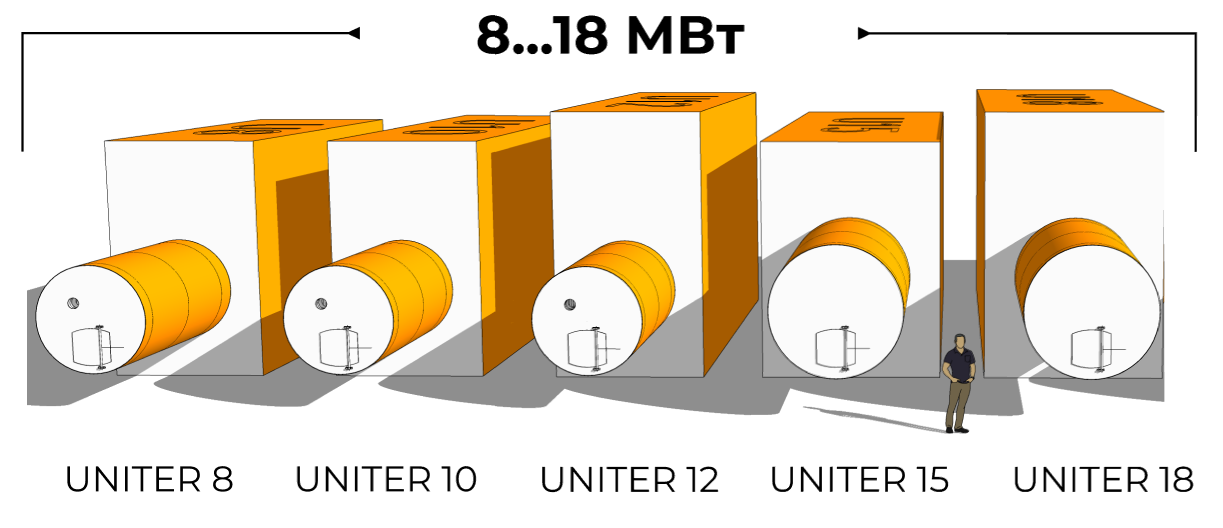

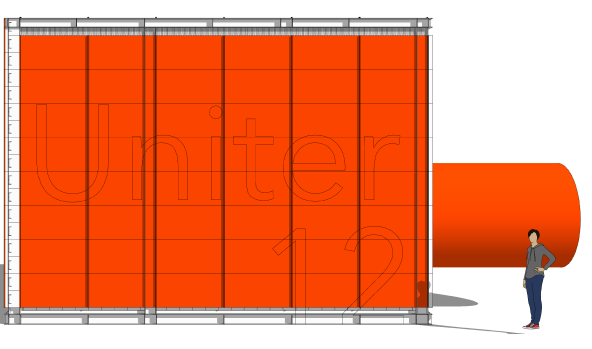

UNITER 8 / 10 / 12 / 15 / 18

A series of soft-lined prismatic chambers with power steps of 2 and 3 MW. Built on the basis of a Uniter camera kit and a Samum burner. Simple installation, modularity and easy locking with optional devices.

UNITER 8 |

||||||||||||||||||||||||||||||

| 8 MW | ||||||||||||||||||||||||||||||

UNITER 10 |

||||||||||||||||||||||||||||||

| 10 MW | ||||||||||||||||||||||||||||||

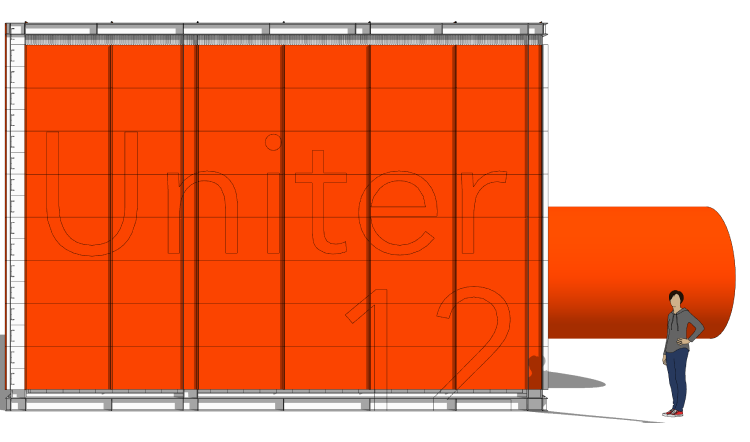

UNITER 12 |

||||||||||||||||||||||||||||||

| 12 MW | ||||||||||||||||||||||||||||||

UNITER 15 |

||||||||||||||||||||||||||||||

| 15 MW | ||||||||||||||||||||||||||||||

UNITER 18 |

||||||||||||||||||||||||||||||

| 18 MW | ||||||||||||||||||||||||||||||

| GAS HEAT GENERATOR (direct heating) | UNITER 8 | UNITER 10 | UNITER 12 | UNITER 15 | UNITER 18 |

|---|---|---|---|---|---|

| Heat capasity of the burner, MW | 8,0 | 10,0 | 12,0 | 15,0 | 18,0 |

| Burner model | Samum 15/8 | Samum 15/10 | Samum 15/12 | Samum 18/15 | Samum 18/18 |

| Efficiency coefficient of the heat generator, % | 95% | 95% | 95% | 95% | 95% |

| Thermal capacity of the heat generator, MW | 7,6 | 9,5 | 11,4 | 14,3 | 17,1 |

| Thermal stress, qv, kW/m3 | 150 | 140 | 150 | 140 | 150 |

| Fuel consumption (for sunflower husks), kg/h | 1 855 | 2 320 | 2 785 | 3 480 | 4 175 |

| Temperature of combustion products, °C | 800 | 800 | 800 | 800 | 800 |

| Volume of combustion products, m3/h | 64 000 | 80 100 | 96 100 | 120 100 | 144 100 |

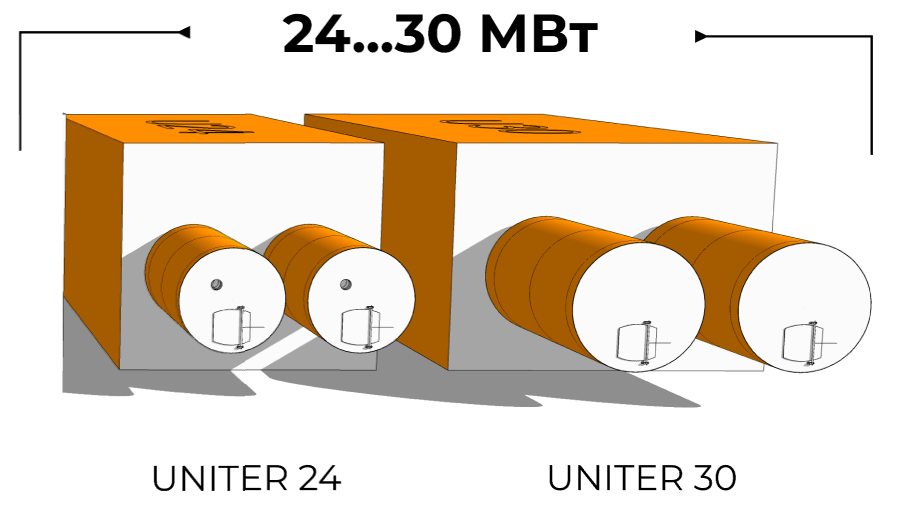

UNITER 24 / UNITER 30

UNITER 24 |

||||||||||||||||||||||||||||||

| 24 MW | ||||||||||||||||||||||||||||||

UNITER 30 |

||||||||||||||||||||||||||||||||

| 30 MW | ||||||||||||||||||||||||||||||||

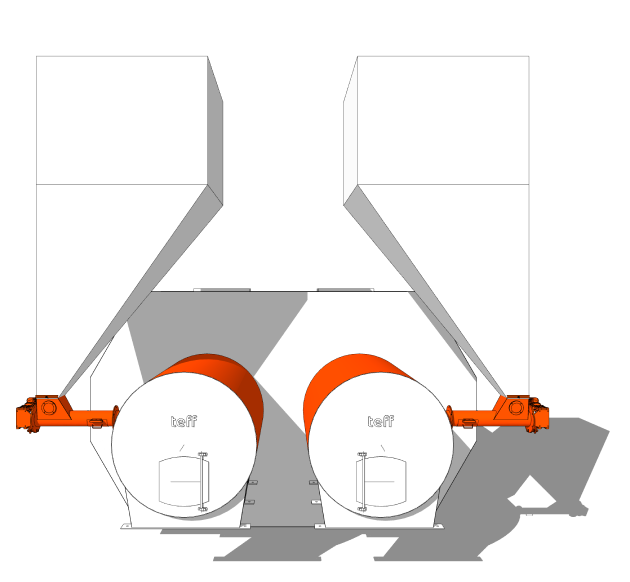

A series of soft-lined prismatic chambers with a power step of 6 MW.

The series of heat generators is built on the basis of a set of Uniter chambers and Samum burners.

To achieve large single capacities, paired designs are used.

| GAS HEAT GENERATOR (direct heating) | UNITER 24 | UNITER 30 |

|---|---|---|

| Heat capasity of the burner, MW | 24,0 | 30,0 |

| Burner model | Samum 15/12 | Samum 18/15 |

| Efficiency coefficient of the heat generator, % | 95% | 95% |

| Thermal capacity of the heat generator, MW | 22,8 | 28,5 |

| Thermal stress, qv, kW/m3 | 140 | 160 |

| Fuel consumption (for sunflower husks), kg/h | 5 565 | 6 960 |

| Temperature of combustion products, °С | 800 | 800 |

| Volume of combustion products, m3/h | 192 100 | 240 300 |

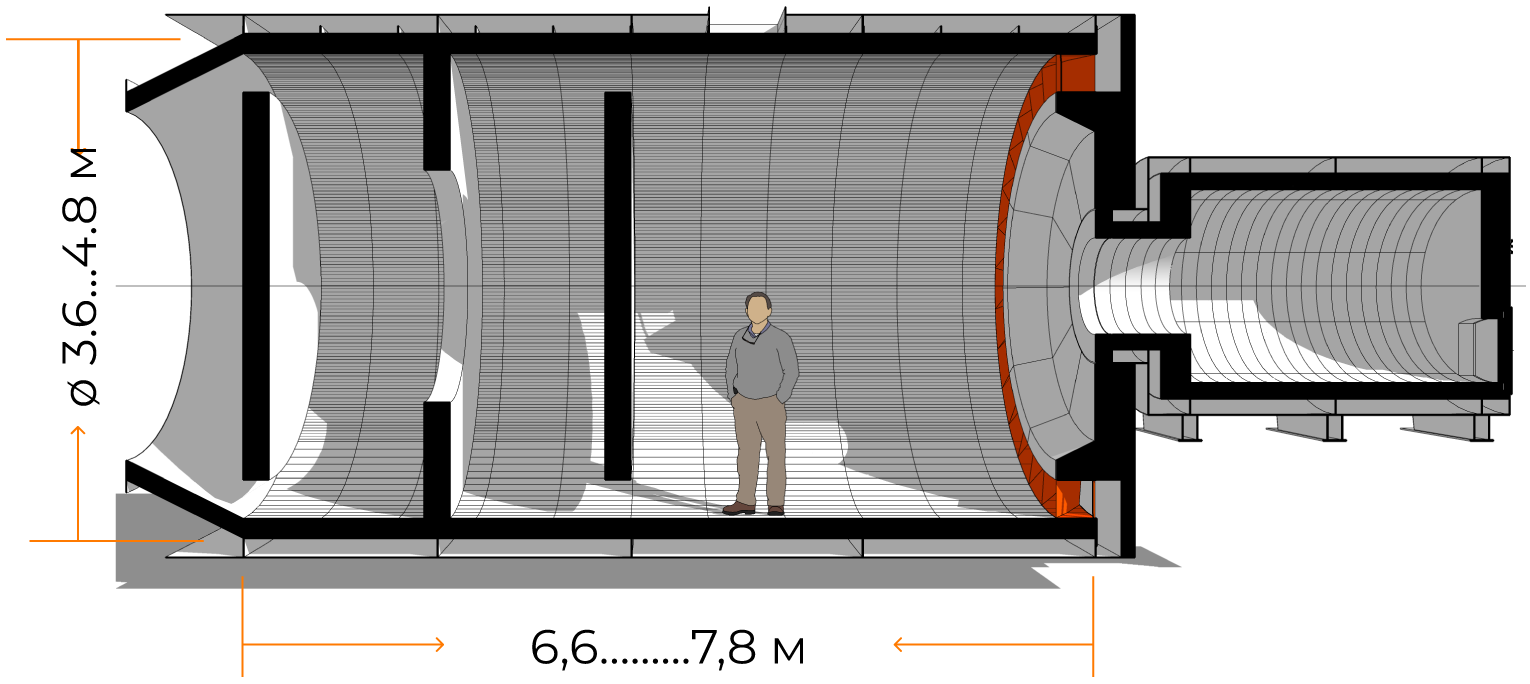

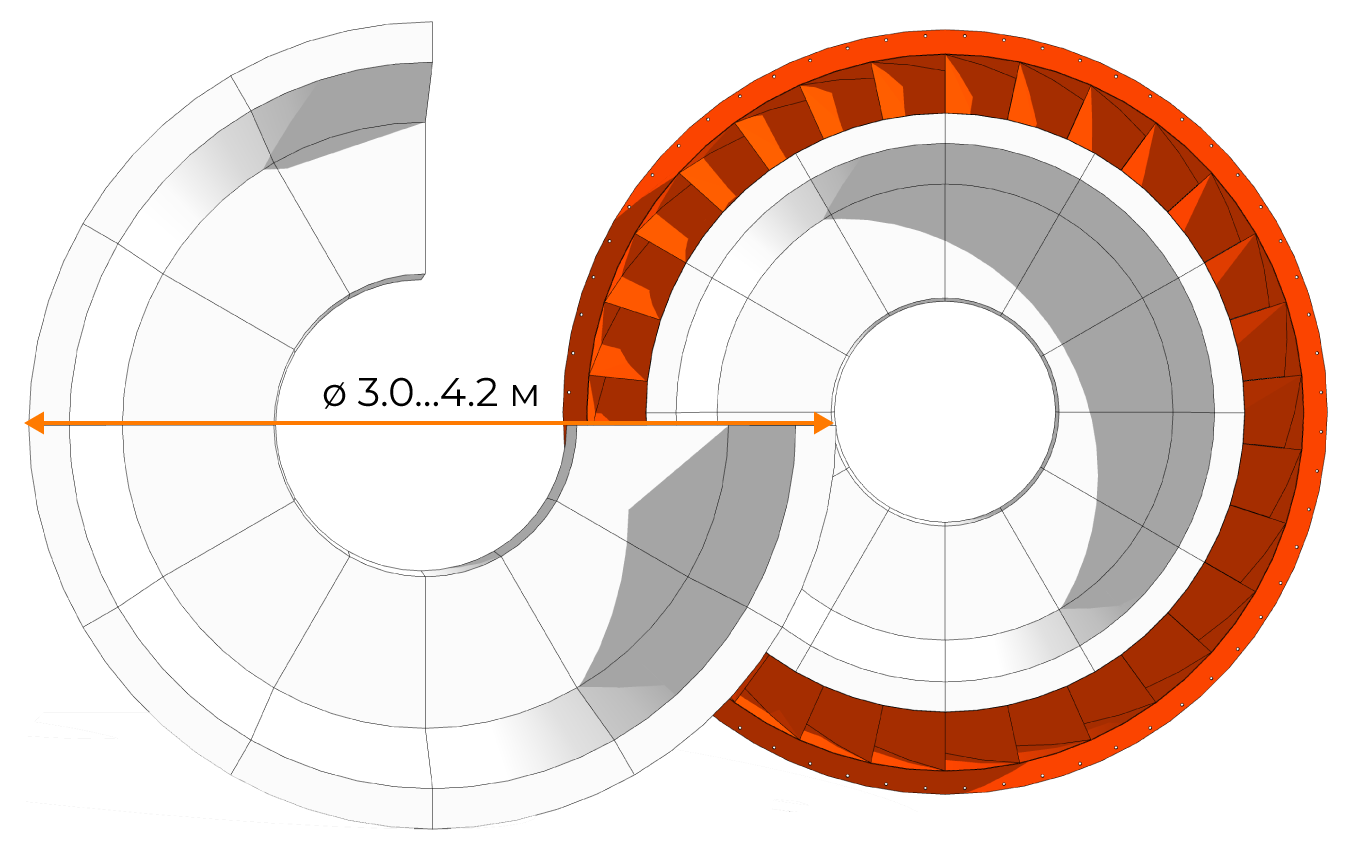

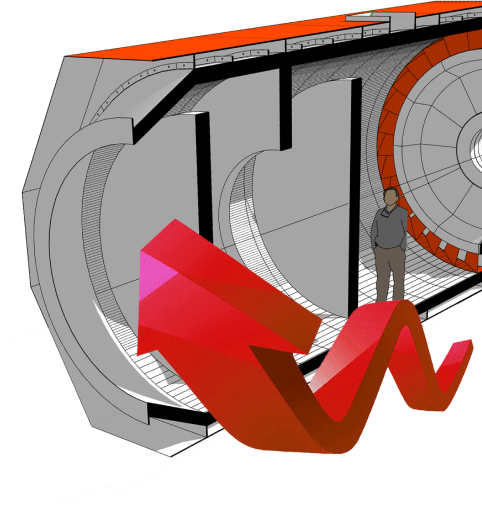

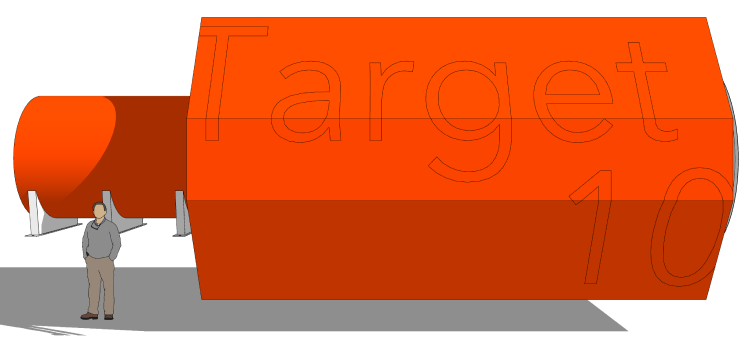

TARGET MIXING CHAMBER

A series of cylindrical chambers with soft lining and forced mixing of flows

ADVANTAGES OF TARGET

- Effectively used cylindrical volume

- Uniform temperature of the mixture due to forced supercharging and swirler

- Partial extinguishing of a spark in a concentric labyrinth channel

- Air cooling of the chamber through the coaxial gap

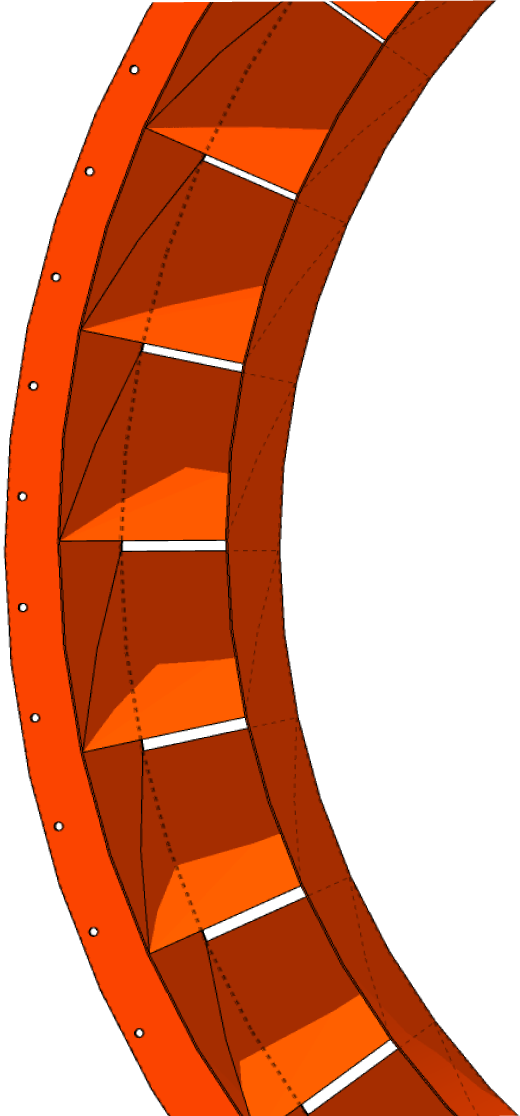

RELIABLE PROTECTION

The front wall and swirler are protected from the direct impact of the torch by a ring of sector blocks made of heat-resistant concrete

EFFICIENT COOLING

The directional device gives the flow of cold air a spiral direction of movement along the cylindrical wall of the chamber, which cools it

EFFICIENT COOLING

The directional device gives the flow of cold air a spiral direction of movement along the cylindrical wall of the chamber, which cools it

UNIFORM TEMPERATURE

The direction of the vortex opposite to the burning flame intensifies the mixing of flows

LABYRINTH CONSTRUCTION

Partial extinguishing of a spark in a concentric labyrinth channel

UNIFORM TEMPERATURE

The direction of the vortex opposite to the burning flame intensifies the mixing of flows

LABYRINTH CONSTRUCTION

Partial extinguishing of a spark in a concentric labyrinth channel

TARGET HEAT GENERATORS

RANGE OF POWERS

TARGET 6

| MW | 4 | 6 | 8 | 10 | 12 | 15 | 18 | 24 | 30 | |||||||||||||||||||||

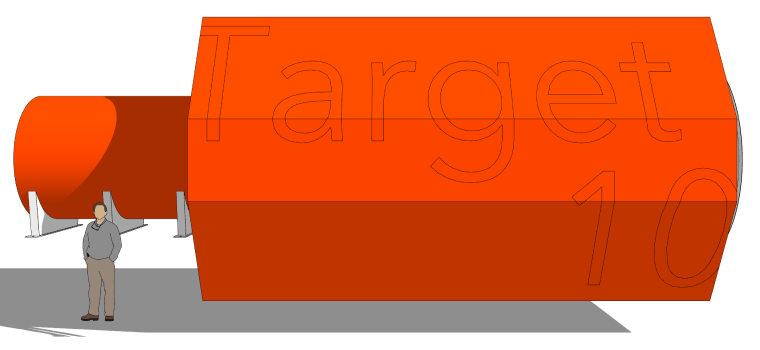

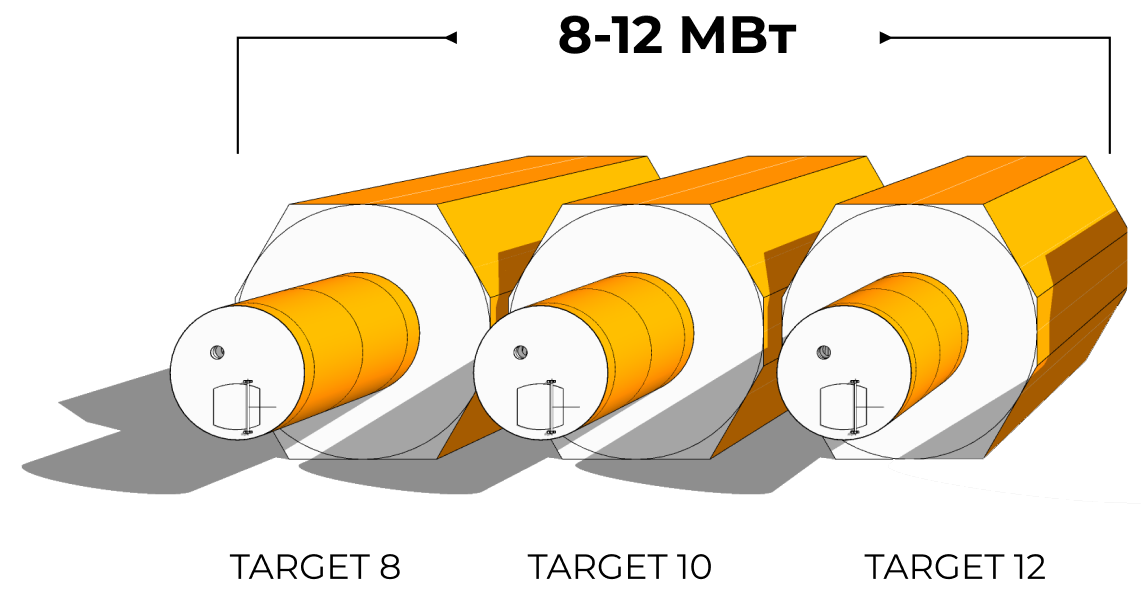

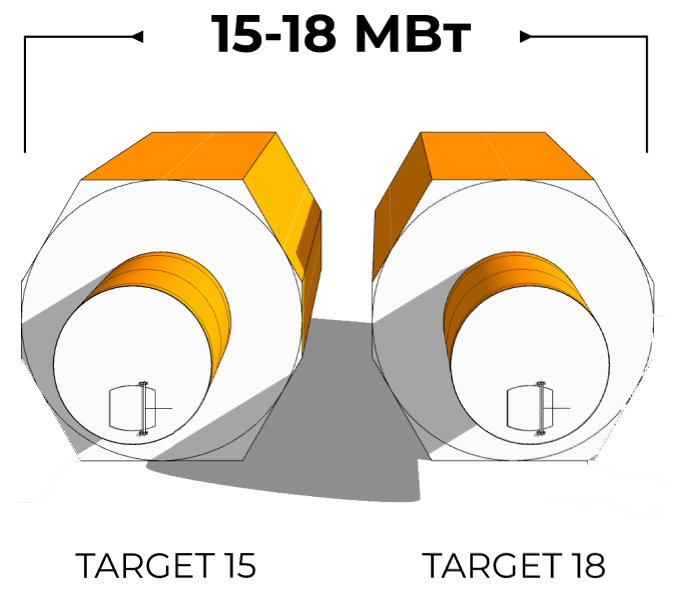

TARGET 8 / 10 / 12 / 15 / 18

A series of cylindrical chambers with soft lining and forced mixing of flows.

Built on the basis of a set of Target cameras and a Samum burner.

Main advantages: simple installation, modularity and easy locking with optional devices

TARGET 8 |

||||||||||||||||||||||||||||||

| 8 MW | ||||||||||||||||||||||||||||||

TARGET 10 |

||||||||||||||||||||||||||||||

| 10 MW | ||||||||||||||||||||||||||||||

TARGET 12 |

||||||||||||||||||||||||||||||

| 12 MW | ||||||||||||||||||||||||||||||

TARGET 15 |

||||||||||||||||||||||||||||||

| 15 MW | ||||||||||||||||||||||||||||||

TARGET 18 |

||||||||||||||||||||||||||||||

| 18 MW | ||||||||||||||||||||||||||||||

| GAS HEAT GENERATOR (direct heating) | TARGET 8 | TARGET 10 | TARGET 12 | TARGET 15 | TARGET 18 |

|---|---|---|---|---|---|

| Heat capasity of the burner, MW | 8,0 | 10,0 | 12,0 | 15,0 | 18,0 |

| Burner model | Samum 15/8 | Samum 15/10 | Samum 15/12 | Samum 18/15 | Samum 18/18 |

| Efficiency coefficient of the heat generator, % | 95% | 95% | 95% | 95% | 95% |

| Thermal capacity of the heat generator, MW | 7,6 | 9,5 | 11,4 | 14,3 | 17,1 |

| Thermal stress, qv, kW/m3 | 150 | 140 | 150 | 140 | 150 |

| Fuel consumption (for sunflower husks), kg/h | 1 855 | 2 320 | 2 785 | 3 480 | 4 175 |

| Temperature of combustion products, °С | 800 | 800 | 800 | 800 | 800 |

| Volume of combustion products, m3/h | 64 000 | 80 100 | 96 100 | 120 100 | 144 100 |

| Camera width in the light, m | 3,0 | 3,0 | 3,0 | 3,6 | 3,6 |

| Camera height in the light, m | 4,8 | 4,8 | 5,4 | 4,8 | 5,4 |

| Camera length in the light, m | 6,0 | 7,5 | 7,5 | 9,0 | 9,0 |

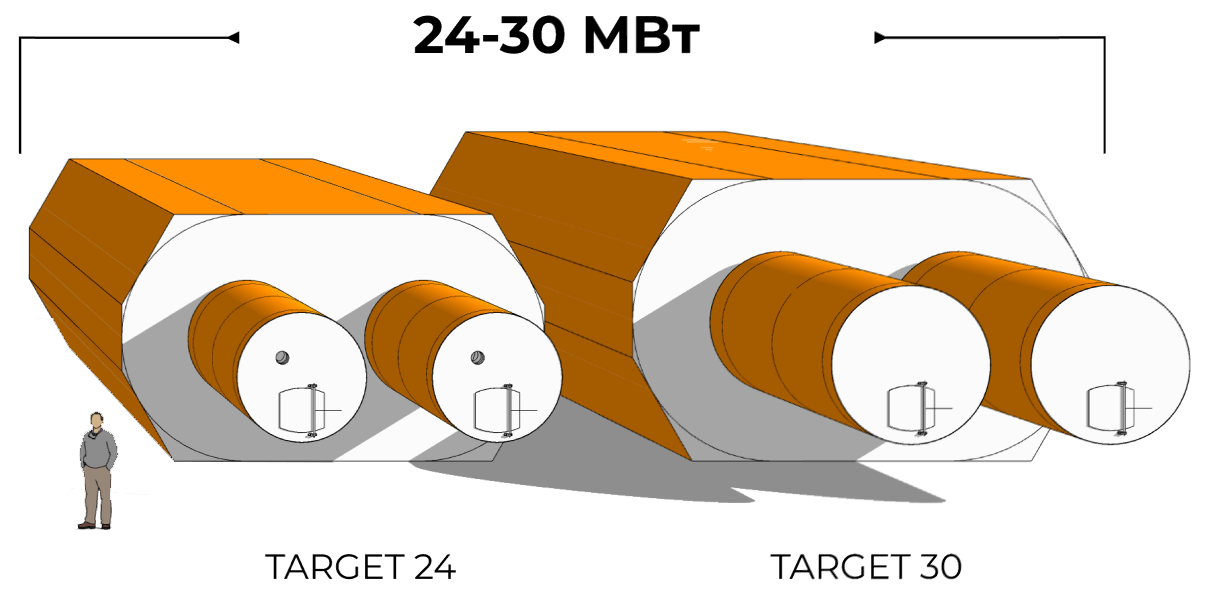

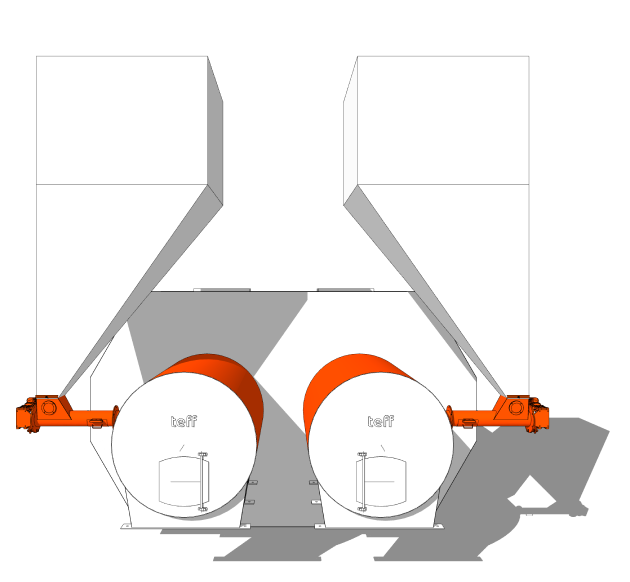

TARGET 24 / TARGET 30

TARGET 24 |

||||||||||||||||||||||||||||||

| 24 MW | ||||||||||||||||||||||||||||||

TARGET 30 |

||||||||||||||||||||||||||||||||

| 30 MW | ||||||||||||||||||||||||||||||||

A series of cylindrical chambers with soft lining and forced mixing of flows. Built on the basis of a set of Target cameras and a Samum burner.

To achieve large individual capacities, paired designs of generators with lateral fuel supply by conveyors are used for rational use of building space.

| GAS HEAT GENERATOR (direct heating) | TARGET 24/2 | TARGET 30/2 | TARGET 36/2 |

|---|---|---|---|

| Heat capasity of the burner, MW | 24,0 | 30,0 | 36,0 |

| Burner model | Samum 15/12 | Samum 18/15 | Samum 18/18 |

| Efficiency coefficient of the heat generator, % | 95% | 95% | 95% |

| Thermal capacity of the heat generator, MW | 22,8 | 28,5 | 34,2 |

| Thermal stress, qv, kW/m3 | 140 | 160 | 160 |

| Fuel consumption (for sunflower husks), kg/h | 5 565 | 6 960 | 8 350 |

| Temperature of combustion products, °С | 800 | 800 | 800 |

| Volume of combustion products, m3/h | 192 100 | 240 300 | 288 300 |

| Camera width in the light, m | 5,4 | 6,0 | 6,9 |

| Camera height in the light, m | 4,8 | 4,8 | 4,8 |

| Camera length in the light, m | 9,0 | 9,0 | 9,0 |