A series of modernized vortex burner devices with combined lining

WORDY COMBUSTION TECHNOLOGY

The principle of operation of the vortex furnace:

With the help of nozzles, blowing is carried out, as a result of which fuel particles are retained and burned in the vortex chamber with high efficiency, which is achieved due to their suspended state in the vortex flow.

The particles are held in the chamber by the flow of flue gases supplied from the gas outlet window. Then, in the afterburning chamber, larger portions of fuel that have burned out completely are processed.

Due to this mechanism, vortex furnaces allow the most efficient use of fine-fraction fuel, as well as biomass of various particle dispersions.

For the rational use of building space, both front and side fuel supply by conveyors is also performed.

RANGE OF POWERS

SAMUM 12/4

| MW | 4 | 6 | 8 | 10 | 12 | 15 | 18 | 21 | 24 | 30 | 36 | ||||||||||||||||||||||||

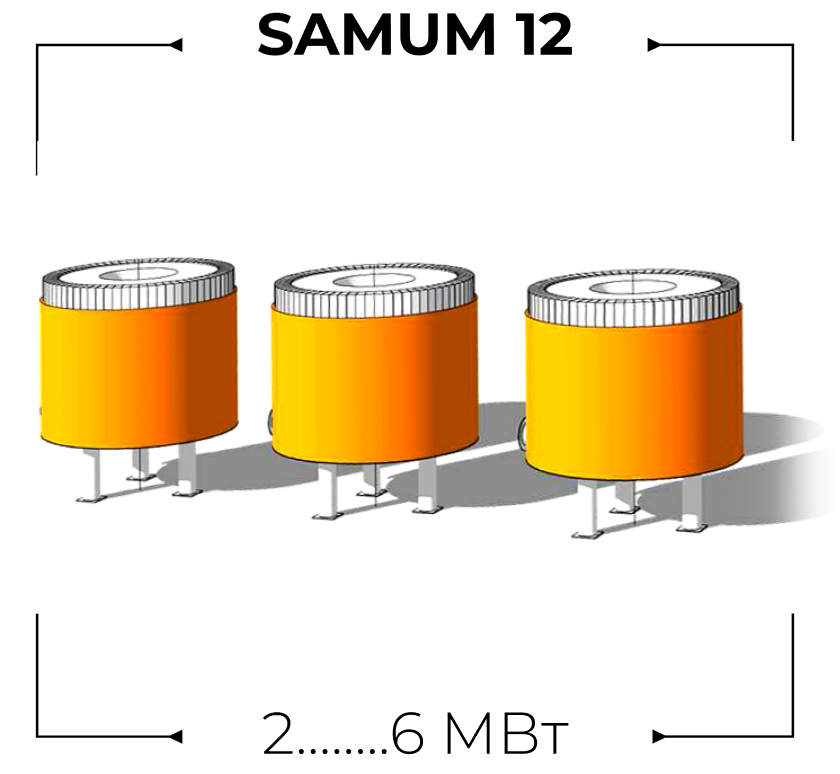

SAMUM 12

SAMUM 12/2 |

||||||||||||||||||||||||||||||

| 2 MW | ||||||||||||||||||||||||||||||

SAMUM 12/4 |

||||||||||||||||||||||||||||||

| 4 MW | ||||||||||||||||||||||||||||||

SAMUM 12/6 |

||||||||||||||||||||||||||||||

| 6 MW | ||||||||||||||||||||||||||||||

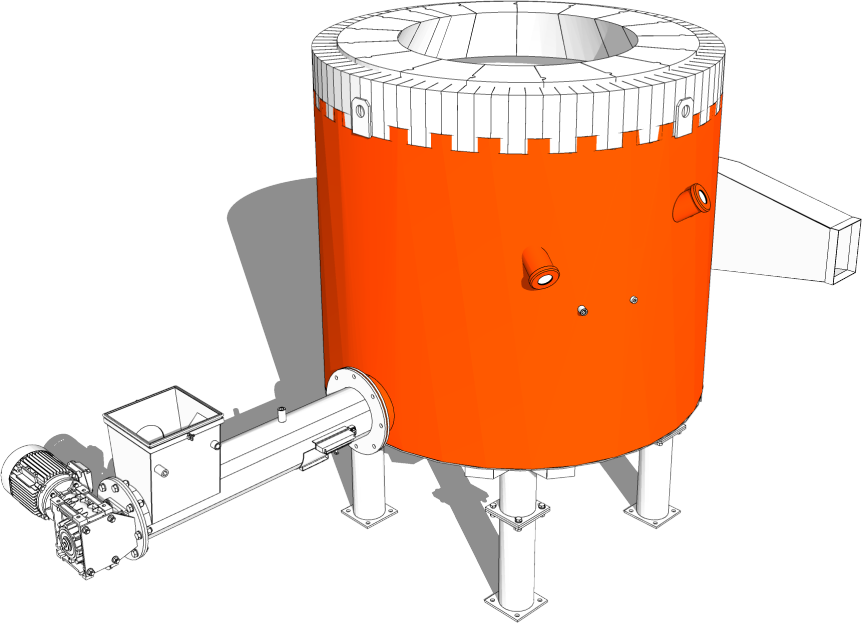

Samum 12 is a modernized series of vortex burners, designed on the basis of burners of the PV series, taking into account extensive experience in their operation

The burners of the SAMUM 12 series with a capacity of 2-6 MW (with a power step of 2 MW) are manufactured in a vertical arrangement with a conical grate and one high-pressure fan. The minimum working length of the feeding auger (without motor-reducer) is 1.2 m.

| SWIRL BURNER | SAMUM 12/2 | SAMUM 12/4 | SAMUM 12/6 |

|---|---|---|---|

| Thermal capasity, MW | 2,0 | 4,0 | 6,0 |

| Adjustment range,% | 40…120 | 40…120 | 40…120 |

| Fuel consumption, kg/h, at Qnr=15,5 MJ/kg (for sunflower huks) | 460 | 930 | 1 390 |

| When Qnr = 19,0 MJ/kg (for wooden pellets) | 380 | 760 | 1 140 |

| When Qnr = 17,0 MJ/kg (for cleaning waste pellets) | 420 | 850 | 1 270 |

| At Qnr = 13,0 MJ/kg (for rice huks) | 550 | 1 110 | 1 660 |

| At Qnr = 12,0 MJ/kg (for wood flinders Wp = 30%) | 590 | 1 180 | 1 770 |

| Electricity consumptoin, kW | 15,0 | 22,0 | 30,0 |

| Implementation | vertical | vertical | vertical |

| The diameter of the output nozzle in the light, mm | 600 | 600 | 600 |

| Height (without hopper), mm | 2 050 | 2 050 | 2 050 |

| Width (without fans), mm | 1 700 | 1 700 | 1 700 |

| Length (without feeding auger), mm | 2 100 | 2 100 | 2 100 |

| Mass in assembly, kg | 4 500 | 4 500 | 4 500 |

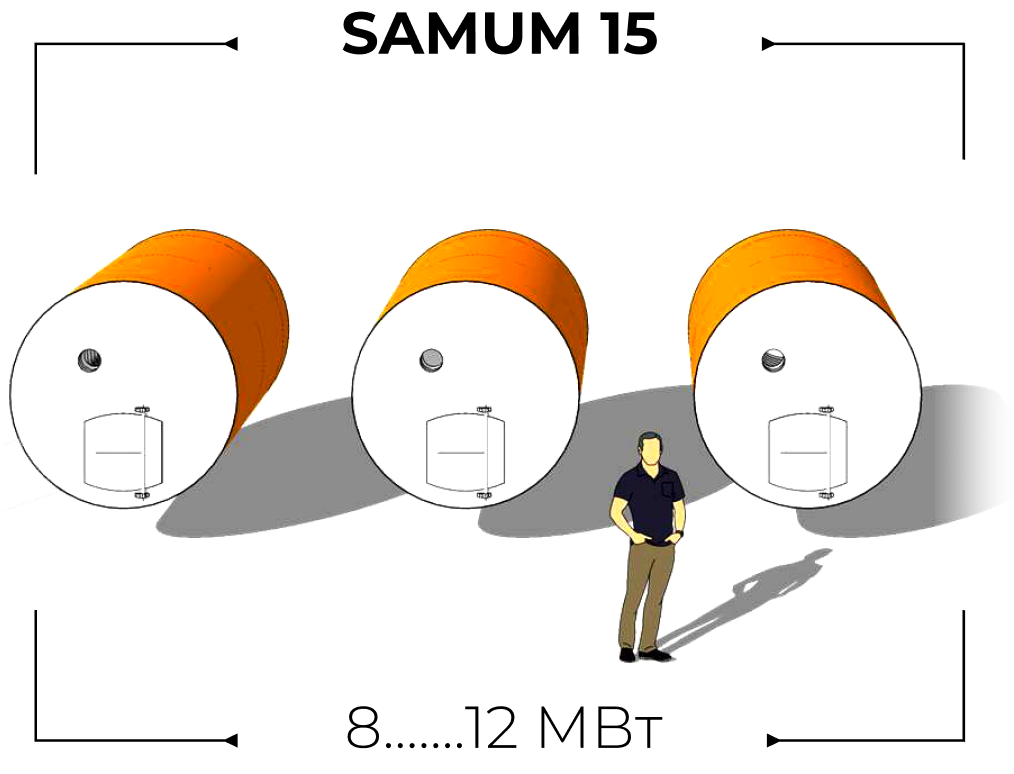

SAMUM 15

SAMUM 15/8 |

||||||||||||||||||||||||||||||

| 8 MW | ||||||||||||||||||||||||||||||

SAMUM 15/10 |

||||||||||||||||||||||||||||||

| 10 MW | ||||||||||||||||||||||||||||||

SAMUM 15/12 |

||||||||||||||||||||||||||||||

| 12 MW | ||||||||||||||||||||||||||||||

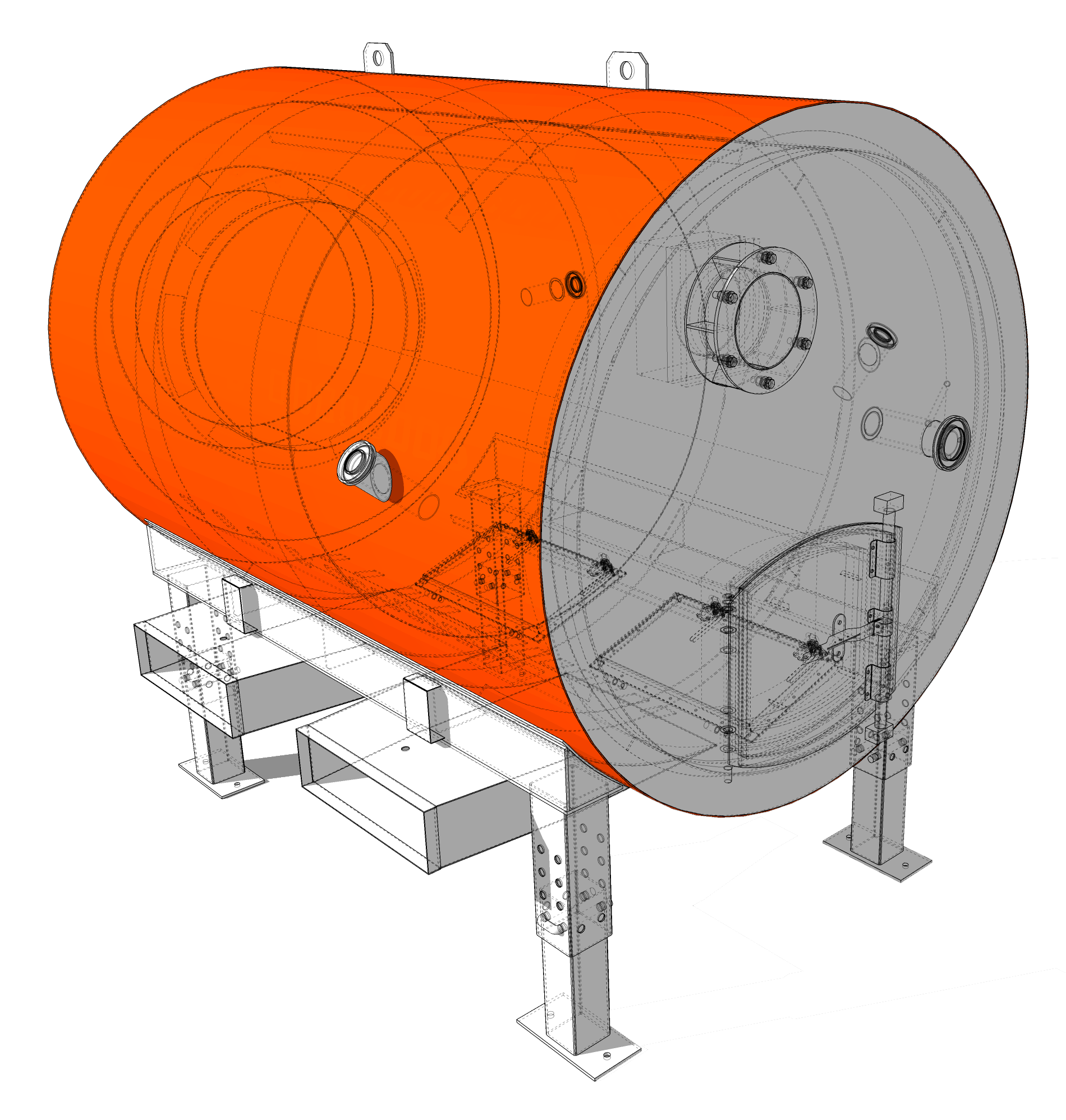

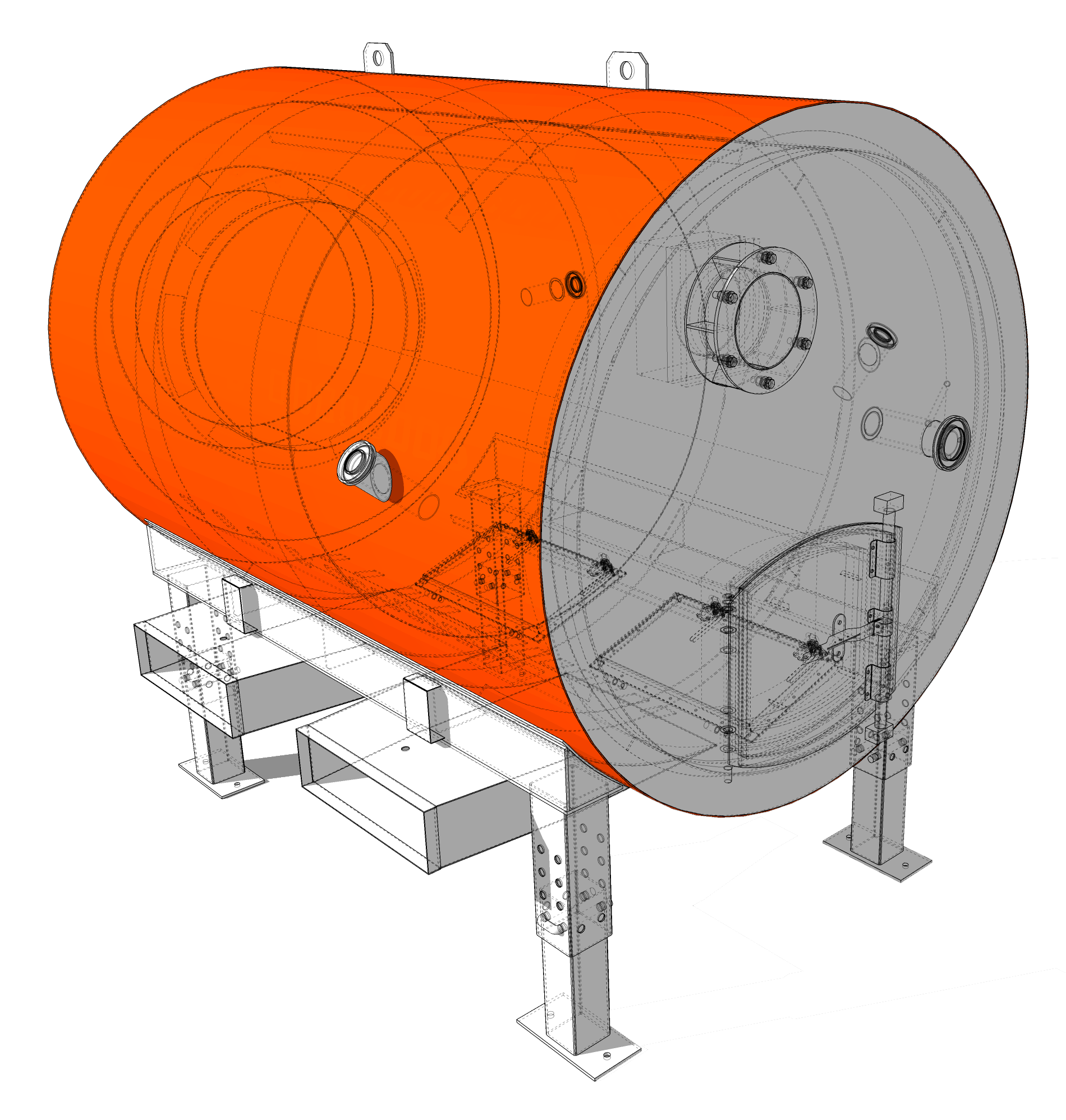

Samum 15 is a modernized series of vortex burners, designed on the basis of PVG series burners, taking into account extensive experience in their operation.

Burners of the SAMUM 15 series with a capacity of 8-12 MW (with a power step of 2 MW) are manufactured in a horizontal arrangement with two high-pressure fans. The minimum working length of the feeding auger (without motor-reducer) is 1.2 m.

| SWIRL BURNER | SAMUM 15/8 | SAMUM 15/10 | SAMUM 15/12 |

|---|---|---|---|

| Thermal capasity, MW | 8,0 | 10,0 | 12,0 |

| Adjustment range,% | 40…100 | 40…100 | 40…100 |

| Fuel consumption, kg/h, at Qnr=15,5 MJ/kg (for sunflower huks) | 1 855 | 2 320 | 2 785 |

| When Qnr = 19,0 MJ/kg (for wooden pellets) | 1 545 | 1 935 | 2 320 |

| When Qnr = 17,0 MJ/kg (for cleaning waste pellets) | 1 730 | 2 160 | 2 590 |

| At Qnr = 13,0 MJ/kg (for rice huks) | 2 260 | 2 825 | 3 390 |

| At Qnr = 12,0 MJ/kg (for wood flinders Wp = 30%) | 2 410 | 3 015 | 3 615 |

| Electricity consumptoin, kW | 74,0 | 90,0 | 110,0 |

| Implementation | horizontal | horizontal | horizontal |

| The diameter of the output nozzle in the light, mm | 750 | 750 | 750 |

| Height (without hopper), mm | 2 500 | 2 500 | 2 500 |

| Width (without fans), mm | 2 000 | 2 000 | 2 000 |

| Length (without feeding auger), mm | 3 150 | 3 150 | 3 150 |

| Mass in assembly, kg | 6 000 | 6 000 | 6 000 |

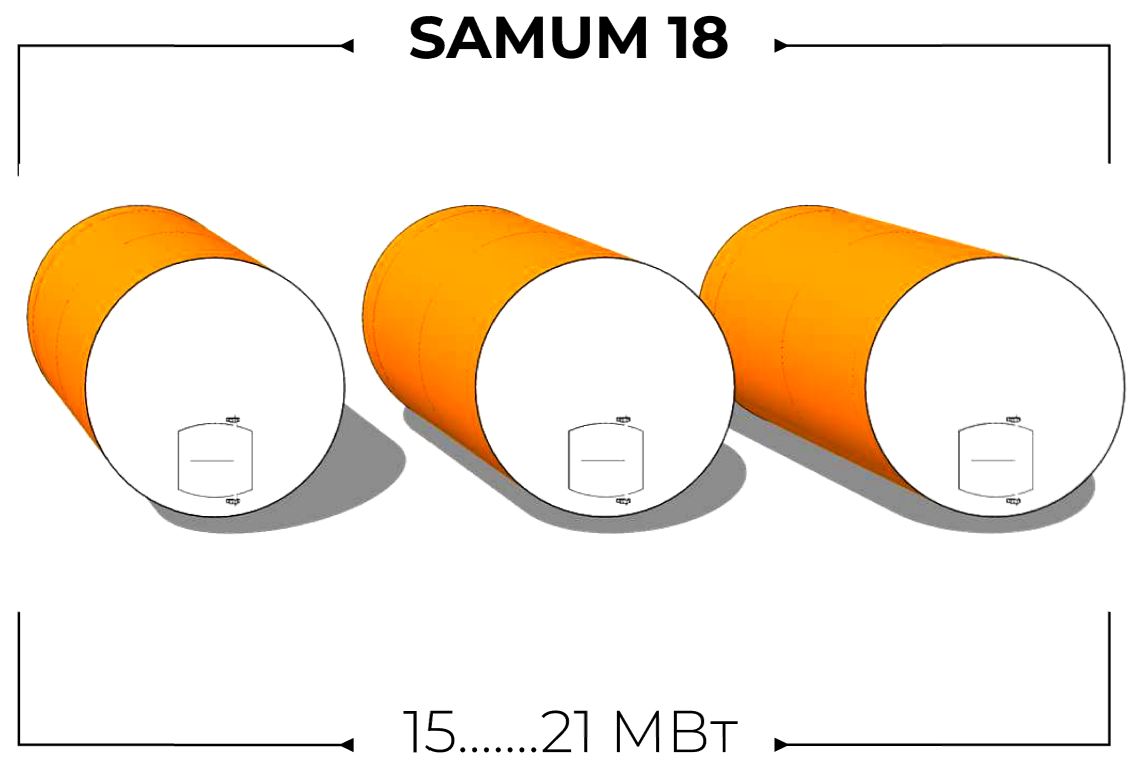

SAMUM 18

SAMUM 18/15 |

||||||||||||||||||||||||||||||

| 15 MW | ||||||||||||||||||||||||||||||

SAMUM 18/18 |

||||||||||||||||||||||||||||||

| 18 MW | ||||||||||||||||||||||||||||||

SAMUM 18/21 |

||||||||||||||||||||||||||||||

| 21 MW | ||||||||||||||||||||||||||||||

Samum 18 is a modernized series of vortex burners, designed on the basis of PVG series burners, taking into account extensive experience in their operation.

Burners of the SAMUM 18 series with a capacity of 15-21 MW (with a power step of 3 MW) are manufactured in a horizontal arrangement with two high-pressure fans. The minimum working length of the feeding auger (without motor-reducer) is 1.2 m.

| SWIRL BURNER | SAMUM 18/15 | SAMUM 18/18 | SAMUM 18/21 |

|---|---|---|---|

| Thermal capasity, MW | 15,0 | 18,0 | 21,0 |

| Adjustment range,% | 40…100 | 40…100 | 40…100 |

| Fuel consumption, kg/h, at Qnr=15,5 MJ/kg (for sunflower huks) | 3 480 | 4 175 | 4 870 |

| When Qnr = 19,0 MJ/kg (for wooden pellets) | 2 900 | 3 480 | 4 060 |

| When Qnr = 17,0 MJ/kg (for cleaning waste pellets) | 3 240 | 3 890 | 4 535 |

| At Qnr = 13,0 MJ/kg (for rice huks) | 4 235 | 5 085 | 5 930 |

| At Qnr = 12,0 MJ/kg (for wood flinders Wp = 30%) | 4 520 | 5 425 | 6 325 |

| Electricity consumptoin, kW | 110,0 | 150,0 | 180,0 |

| Implementation | horizontal | horizontal | horizontal |

| The diameter of the output nozzle in the light, mm | 900 | 900 | 900 |

| Height (without hopper), mm | 3 000 | 3 000 | 3 000 |

| Width (without fans), mm | 2 400 | 2 400 | 2 400 |

| Length (without feeding auger), mm | 3 650 | 3 650 | 3 650 |

| Mass in assembly, kg | 8 000 | 8 000 | 8 000 |

SAMUM 21

SAMUM 21/24 |

||||||||||||||||||||||||||||||

| 24 MW | 12 MW | |||||||||||||||||||||||||||||

| 12 MW | ||||||||||||||||||||||||||||||

SAMUM 21/30 |

||||||||||||||||||||||||||||||

| 30 MW | 15 MW | |||||||||||||||||||||||||||||

| 15 MW | ||||||||||||||||||||||||||||||

SAMUM 21/36 |

||||||||||||||||||||||||||||||

| 36 MW | 18 MW | |||||||||||||||||||||||||||||

| 18 MW | ||||||||||||||||||||||||||||||

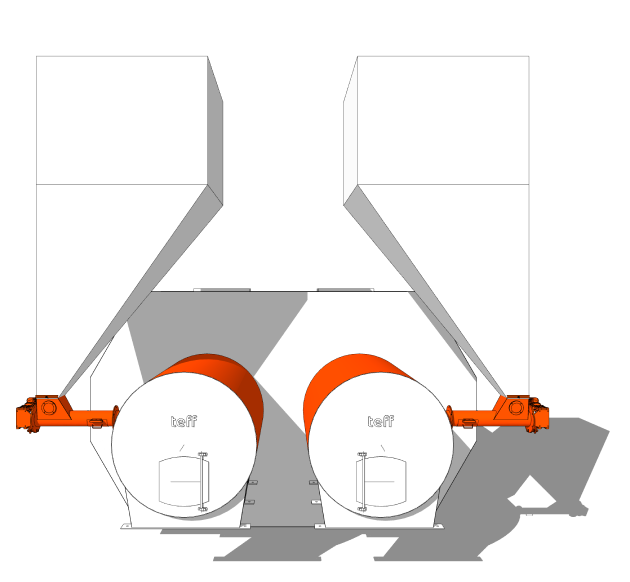

Samum 21 is a modernized series of vortex burners, designed on the basis of PVG series burners, taking into account extensive experience in their operation

Burners of the SAMUM 21 series with a capacity of 24-36 MW (with a power step of 6 MW) are manufactured in a horizontal arrangement with two high-pressure fans. The minimum working length of the feeding auger (without motor-reducer) is 1.2 m.

| SWIRL BURNER | SAMUM 21/24 | SAMUM 21/30 | SAMUM 21/36 |

|---|---|---|---|

| Thermal capasity, MW | 24,0 | 30,0 | 36,0 |

| Adjustment range,% | 40…100 | 40…100 | 40…100 |

| Fuel consumption, kg/h, at Qnr=15,5 MJ/kg (for sunflower huks) | 5 565 | 6 960 | 8 350 |

| When Qnr = 19,0 MJ/kg (for wooden pellets) | 4 640 | 5 800 | 6 955 |

| When Qnr = 17,0 MJ/kg (for cleaning waste pellets) | 5 185 | 6 480 | 7 775 |

| At Qnr = 13,0 MJ/kg (for rice huks) | 6 780 | 8 475 | 10 170 |

| At Qnr = 12,0 MJ/kg (for wood flinders Wp = 30%) | 7 230 | 9 040 | 10 845 |

| Electricity consumptoin, kW | |||

| Implementation | horizontal | horizontal | horizontal |

| The diameter of the output nozzle in the light, mm | 1 050 | 1 050 | 1 050 |

| Height (without hopper), mm | 3 150 | 3 150 | 3 150 |

| Width (without fans), mm | 2 700 | 2 700 | 2 700 |

| Length (without feeding auger), mm | |||

| Mass in assembly, kg | 10 000 | 10 000 | 10 000 |